The Feasibility Fallacy: Why Teams Still Trip Over Technical Feasibility

I once greenlit a “quick win” that was supposed to make a customer demo sparkle. Small feature, tiny scope, easy engineering. Halfway through the sprint, the team tripped over a constraint buried in an upstream API. Sadly, the fix wasn’t a tweak. It was a months-long detour. We hadn’t skipped discovery. We hadn’t skipped design. We skipped the thing everyone skips when they’re in a hurry: a real technical feasibility check.

That scramble reinforced two uncomfortable truths. First, most teams aren’t bad at delivery… they’re bad at admitting what they don’t know. Second, the fastest way to look slow is to pretend feasibility doesn’t matter.

If you’ve ever had a “how hard could it be?” moment blow up your roadmap, this is for you. Feasibility assessment is the quiet muscle that keeps great product teams honest, aligned, and scalable. When you treat it like a blocker, it punishes you. When you treat it like a guide, it propels you.

Need the quick definition? See “Technical Feasibility” in the glossary for the short version and a step-by-step assessment you can run with your team.

When poor feasibility checks quietly derail good products

Problems with how teams handle technical feasibility rarely start loud. They hide in assumptions, build up friction, and surface when it’s already too late.

Through my work coaching product leaders, consulting with growing companies, and seeing thousands of teams use ProdPad, I’ve seen nearly every version of this. The context changes, but the patterns don’t.

Here are three real-world examples of how teams get this wrong, and what finally helped them get it right.

1) The late discovery

A retail scale-up was racing to launch a “Buy online, Pick up In-Store” sort of feature before Black Friday. On paper, it seemed simple. Though weeks into development, they realized their store systems handled stock updates in nightly batches, not in real time. Fixing that meant rewriting two other integrations.

The team didn’t need a new roadmap, they needed a new habit: talking about technical constraints before deadlines existed. The solution came when the product lead started running “Feasibility Five” sessions: short, five-minute gut checks with engineering whenever a new idea hit the backlog. The system didn’t magically sync faster, but their decision-making did.

2) The unclear owner

A healthcare startup had an ambitious vision for real-time patient monitoring using consumer wearables. Everyone assumed someone else had checked what was possible. Design thought engineering had vetted the data pipeline. Engineering assumed compliance had signed off on the regulatory risk. Nobody had.

By the time they reached testing, they were drowning in edge cases and paperwork. The turning point came when they added a clear owner for feasibility checks: the tech lead, supported by a Product Manager who tracked timing and outcomes. Within a month, new features went through quick validation spikes. The flashy “real-time” idea became a simpler “daily summary” that was compliant, scalable, and far easier to ship.

3) The overconfident rebuild

One enterprise SaaS company I worked with decided to split their monolith into microservices. They had done some technical feasibility review work… but only once, at the start. A year later, every new feature had to cross three services and two teams. Progress slowed, quality dropped, and everyone blamed the process.

The problem wasn’t the architecture. It was the belief that feasibility validation is something you finish, not something you revisit. Once they began checking technical dependencies at every quarterly planning cycle, teams started sequencing work differently. A few months later, releases were faster and outages were down.

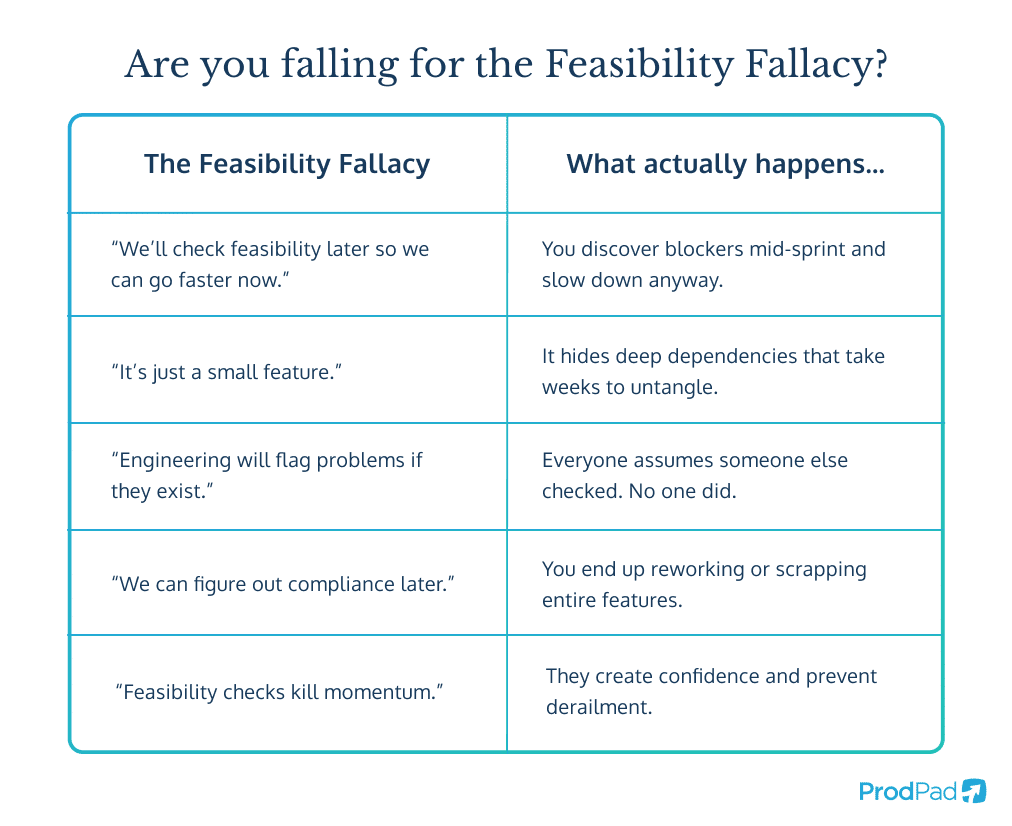

The Feasibility Fallacy

After years of watching teams grow, scale, and occasionally implode, I’ve noticed a recurring belief that gets everyone into trouble: the idea that checking technical feasibility slows you down. It’s what I call The Feasibility Fallacy.

It’s the comforting illusion that momentum equals progress. You’ve got stakeholder pressure, ambitious OKRs, a shiny new pitch deck. The team’s shipping fast, and questioning feasibility feels like heresy. But here’s the uncomfortable truth: skipping those checks doesn’t make you faster. It just means you’ll hit the brakes later, usually when it’s least convenient.

The fallacy shows up in a few predictable ways.

Binary thinking

Teams still treat their technical feasibility studies like a yes-or-no gate: “Can we build it?” Instead, it should be an ongoing question: “What would it take to build this well?”

Every complex product I’ve ever seen was born out of that “yes, if…” conversation.

Checking at the wrong time

Some teams dive into checking feasibility too early, before discovery has shaped the problem. Others wait until they’ve already promised delivery dates and budgets. Both approaches are expensive.

The best teams I’ve seen weave light-touch feasibility checks throughout the process: early enough to learn, late enough to have real data.

The ownership vacuum

I’ve lost count of how many times I’ve asked, “Who owns technical feasibility here?” and been met with silence. Product assumes Engineering will handle it. Engineering assumes Product will flag it. In the gap, decisions get made by momentum instead of evidence.

The result isn’t just rework or tech debt. It’s eroded trust. When leaders see slipping timelines and half-delivered features, they assume teams are underperforming, when in reality, they just built blind.

I tell teams this all the time: you can skip feasibility review, but you can’t skip its consequences.

What technical feasibility reviews are actually for

Technical feasibility isn’t a permission slip. It’s a reality check. It’s what keeps ambition honest.

In healthy product teams, feasibility checks act like a mirror: reflecting what’s real, not what you wish were true. The goal isn’t to say no. It’s to make sure your yes actually means something.

Here’s what the best teams use technical feasibility checks for:

To validate assumptions

Every backlog item hides a few guesses: about systems, data, integrations, scalability. Feasibility estimates are how you surface those guesses before they become blockers.

To expose hidden constraints

I once coached a fintech team that wanted to offer “instant” payments. Their engineers quietly pointed out that the word instant meant something very different to the banking APIs they relied on. Catching that early turned an impossible feature into a same-day one that worked and built trust with customers.

To align the team

When engineers, designers, and PMs explore feasibility together, they stop fighting over “what’s possible” and start co-creating how to make it work. You see this when a designer says, “If that API limit’s the blocker, what if we simplify the interaction?” That’s not compromise, that’s product thinking.

To make trade-offs visible

In one enterprise client, I watched a senior PM completely change how executives saw feasibility. Instead of hiding technical risks in delivery slides, she surfaced them right next to business value. “This feature is possible, but here’s what it will cost us in performance.” Suddenly this feasibility estimate wasn’t a blocker: it was a lens for strategic choice.

When teams understand this, the technical feasibility assessment stage stops being a hurdle and becomes the foundation of good decision-making.

Why teams still dodge the conversation

Every PM knows the moment when they spot a looming technical risk but hesitate to bring it up. You see the problem, but you also see the exec calendar and the looming deadline. It’s tempting to think, “We’ll figure it out later.”

I’ve been there, and I’ve watched enough teams to know the real reasons why feasibility gets brushed aside.

Speed theatre. The culture rewards shipping, not learning. Raising feasibility risks sounds like negativity, so people hold their tongue until it’s too late.

Hero culture. Founders and leaders love big, bold bets. It’s hard to say, “We might not be able to deliver this yet” when everyone’s bought into the vision.

Lack of structure. If you don’t have a clear, lightweight process for checking feasibility, it always feels optional. Teams that formalize even a simple “five-minute check with engineering” find it becomes second nature.

Fear of conflict. When feasibility conversations happen too late, they turn into blame. Product feels blindsided, engineering feels unheard. The antidote is to make these discussions early and recurring, so honesty feels normal, not confrontational.

The most mature teams I’ve coached don’t avoid feasibility conversations. They expect it to challenge their assumptions. They see that tension as a sign the process is working.

How to build feasibility checks into your process without slowing down

I often hear teams say, “We don’t have time for another step.” The truth is, you’re already doing feasibility validation work. You’re just doing it reactively, mid-sprint, when it’s at its most expensive. The trick is to bring that same thinking forward so it becomes a rhythm, not a fire drill.

Over the years, I’ve seen a few small habits consistently separate the teams who stay nimble from those who burn out chasing ghosts.

Start with the five-minute gut check

Every idea deserves at least a quick sanity scan. When something lands in the backlog, pull in a tech lead and ask, “Does anything here sound impossible, unsafe, or surprisingly complex?” It’s not a meeting. It’s a short conversation that saves everyone from running headfirst into a wall later.

After seeing that other team’s success with their “Feasibility Five” approach (those quick five-minute gut checks I mentioned earlier) I started encouraging other teams to try it too. One group even made it visible: a dedicated Feasibility Five column on their ideas board where the PM and tech lead dropped quick comments. It was small, fast, but powerful context. They caught issues that had been lurking for months in other teams’ backlogs.

Turn assumptions into questions

Every risky idea hides a few unknowns. Write them down. Instead of “API latency might be an issue,” say, “How fast does this API respond under load?” Then give yourself a small, focused spike to find out. One team I coached set a one-day limit for every spike: one question, one day, one clear answer. It made learning quick and kept engineers from vanishing into rabbit holes.

Make feasibility visible

You don’t need new tools. You need better habits inside the ones you already have. In ProdPad, for example, teams log their assumptions and constraints right on the idea itself. That context follows the work through discovery, roadmapping, and delivery. No buried Slack threads. No mystery decisions. Just a clear, living history of what’s true, what’s guessed, and what’s changed.

Run “pre-mortems,” not post-mortems

Before you commit to a big piece of work, ask, “If this fails in production, how would it fail, and what would we wish we’d known?” When I started asking that question in coaching sessions, I watched entire teams rethink their sequencing. Suddenly they were spotting logging gaps, compliance blind spots, and capacity issues they’d never have considered.

Use error budgets as a guide, not a punishment

Some engineering teams use error budgets to decide when to pause feature work and focus on reliability. Product teams can take a similar cue. If problems and rework are piling up, it’s not a speed issue: it’s a signal you’re saying yes before checking if it’s really doable.

The teams that practice these habits don’t move slower. They move with less drag. They spend less time firefighting and more time shipping confidently.

Checking technical feasibility in the AI era

AI has changed what’s technically possible, as well as what’s financially or ethically risky. It’s now trivial to wire up a prototype using an LLM, a no-code integration, or a hosted API. The problem is, that prototype rarely survives contact with production reality.

I’ve worked with a handful of teams this year who learned that the hard way.

One startup built a “smart” assistant for customer support. It looked perfect in early demos, until they realized that every call to their model cost a few cents, and every customer interaction triggered multiple calls. Once they scaled up, their “AI differentiator” became a margin-killer.

Another team trained their own model using customer feedback data, only to find it wasn’t legally theirs to use. They’d assumed because the data was “in the system,” it was fair game. Their legal team disagreed.

These stories aren’t rare. They’re the new normal. Which means your feasibility checks have to evolve too.

When you evaluate ideas that rely on AI, the questions shift:

- Can we predict costs at scale? Many AI tools are usage-based. Feasibility now includes financial feasibility. Will the economics still work when usage grows tenfold?

- Can we meet performance expectations? Latency, quality, and reliability vary widely between models and vendors. You need to measure it under realistic conditions.

- Are we compliant and ethical? Where is your data going? Can you explain model outputs to a regulator or a customer? If not, you have a product risk, not a technical one.

In this new era, technical feasibility isn’t just about whether something can be built. It’s about whether it should be built, and under what safeguards. The best teams treat that as part of discovery, not an afterthought.

Leading technical feasibility with curiosity and transparency

You don’t have to be the most technical person in the room to lead good feasibility discussions. You just have to make it safe to ask uncomfortable questions early.

When I coach product leaders, I tell them that leadership around feasibility isn’t about having the answers. It’s about creating the conditions for honesty.

Start by asking questions that open doors, not corners:

- “What would have to be true for this to ship well?”

- “If we did this and it went wrong, how would it fail?”

- “What’s the smallest version we can build that still gives us a learning signal?”

Make those questions part of your rituals: roadmap reviews, backlog grooming, team kick-offs. The teams that talk about feasibility as freely as they talk about velocity are the ones that stay aligned under pressure.

And don’t shy away from celebrating caution. I once worked with a PM who earned more trust from leadership by parking a high-profile initiative than by shipping it. Their feasibility check showed the integration would tie up two other teams for a quarter. They made the call to wait. When they finally launched months later, it landed cleanly and on schedule. That’s what strategic credibility looks like.

Why strong feasibility practice is a growth advantage

Here’s the paradox most executives miss: teams that talk openly about what’s possible deliver faster, not slower.

When product, design, and engineering co-own technical feasibility, they align around reality. They stop overpromising and start sequencing smarter.

I’ve seen this pattern repeat itself over and over again: in tiny startups and billion-dollar orgs alike.

Teams who keep feasibility in the open:

- Plan with confidence, not guesswork

- Reduce unplanned work by half

- Earn stakeholder trust faster

Feasibility validation isn’t red tape. It’s the scaffolding that lets innovation stand upright. It’s how you get to “yes” without burning out your team or your roadmap in the process.

So next time someone pitches an ambitious idea, don’t respond with “yes” or “no.” Try, “What would have to be true for this to work… and what would it take to make that true?”

That’s the question that separates the teams who get lucky from the teams who get good.

What great teams teach me about getting this right

When I think about the best teams I’ve worked with, the ones who deliver ambitious work without the chaos, they all share one thing in common: they take technical feasibility seriously, but never fear it.

They treat it as part of the craft, not a hurdle. They ask better questions earlier, they leave less to chance, and they build a rhythm of learning into everything they do. They know that progress doesn’t come from pretending things are simple. It comes from understanding the complexity and moving forward anyway.

I’ve seen companies turn themselves around just by building that habit. A five-minute feasibility chat before a roadmap review. A one-day spike that saves a quarter of rework. A culture that sees “not yet” as a sign of maturity, not failure.

That’s the real mark of a strong product organization. Not how quickly you ship, but how rarely you have to apologize for what you shipped.

If you can make technical feasibility part of how your team thinks, quietly, naturally, every day, you’ll find you don’t need heroics to deliver great products. You’ll just build them that way by default.

Ready to see how teams capture feasibility notes next to ideas and strategy?